Success Story: Cost-Effective and Sustainable POP Display Optimization

Client Overview

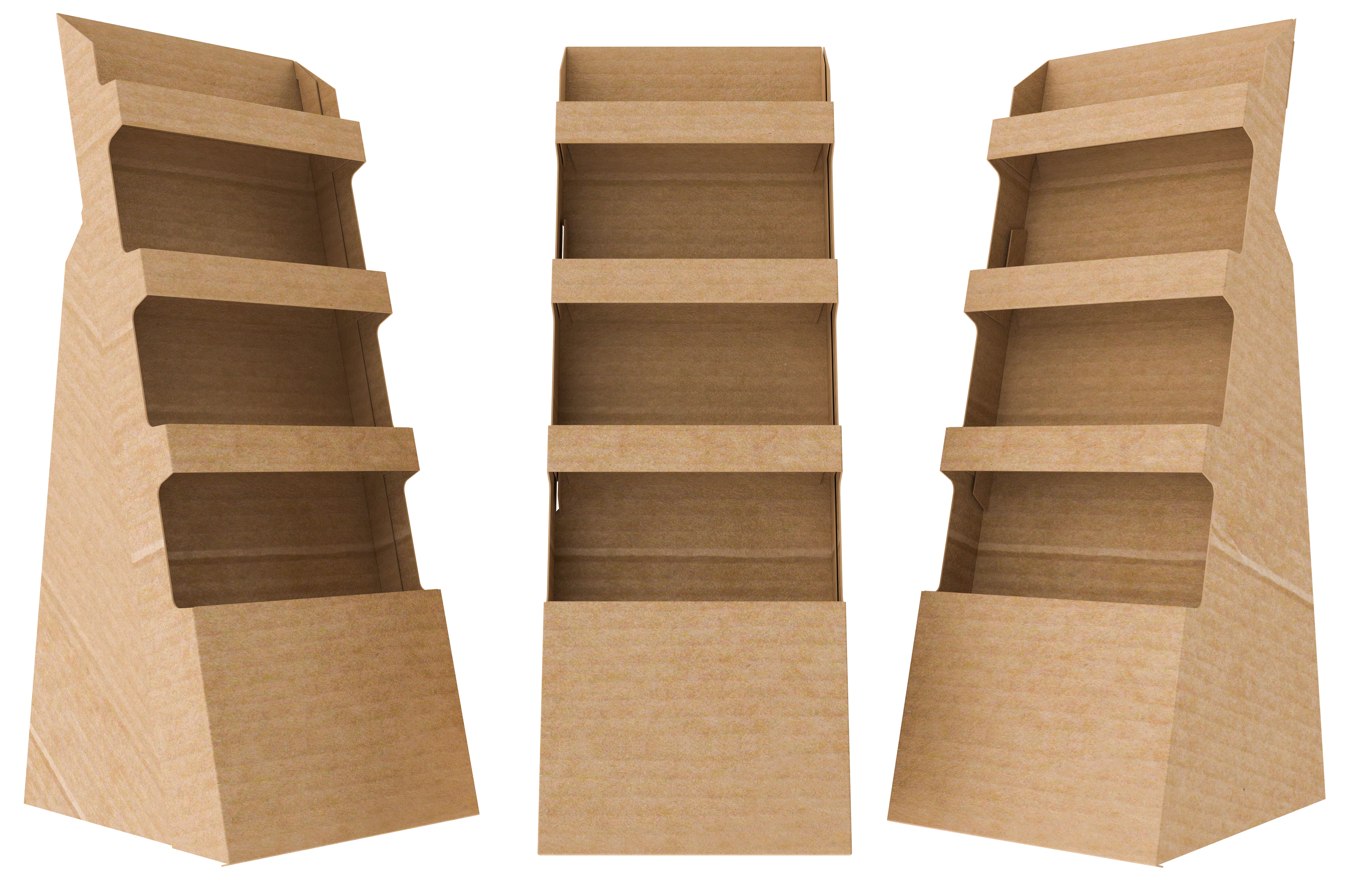

A popular food manufacturer wanted to redesign their existing POP display to enhance its appearance on the retail floor and improve visibility of the primary packs. In addition to the visual upgrades, the client sought to reduce material costs and improve sustainability, all while working within an accelerated development timeline.

The Challenge

The redesign needed to address several key requirements:

Develop a new POP display tray with reduced material costs that aligned with the revised primary pack orientation.

Ensure the primary pack remained highly visible within the display.

Confirm the structure could withstand case compression and meet client ship-testing standards.

Improve overall sustainability through a more efficient packaging design.

These goals had to be met quickly without compromising structural integrity or market impact.

Our Approach

To meet the client’s performance, marketing, and sustainability objectives, Adept executed the following:

Reviewed the billboarded primary pack tray design to understand structural options and visibility opportunities.

Because of the accelerated timeline, Adept identified and leveraged an existing structure capable of meeting marketing requirements with minimal modification.

Collaborated with the supplier to make targeted structural adjustments while maintaining overall strength and durability.

Conducted a show-and-tell review, where the client’s marketing team approved the new structure for meeting all aesthetic and functional expectations without extending the development timeline.

Verified that the revised structure met compression requirements and was capable of withstanding distribution.

Reduced material consumption by 30% (3,090 lbs).

- Delivered $16,000 in material cost savings through the redesigned display.

The Impact

The optimized POP display delivered strong improvements across cost, speed, and performance:

30% reduction in material consumption

$16K in cost savings from material reduction

Faster speed-to-market due to a minimal development timeline

Simplified assembly with improved visibility from multiple viewpoints

- Maintained all structural and distribution requirements

This isn't just a fix. It’s a transformation.

Let’s Talk Efficiency Gains

Want to reduce production costs, increase throughput, or optimize your packaging line? Let’s connect.