Success Story: Cost-Effective and Sustainable POP Display Optimization

Client Overview

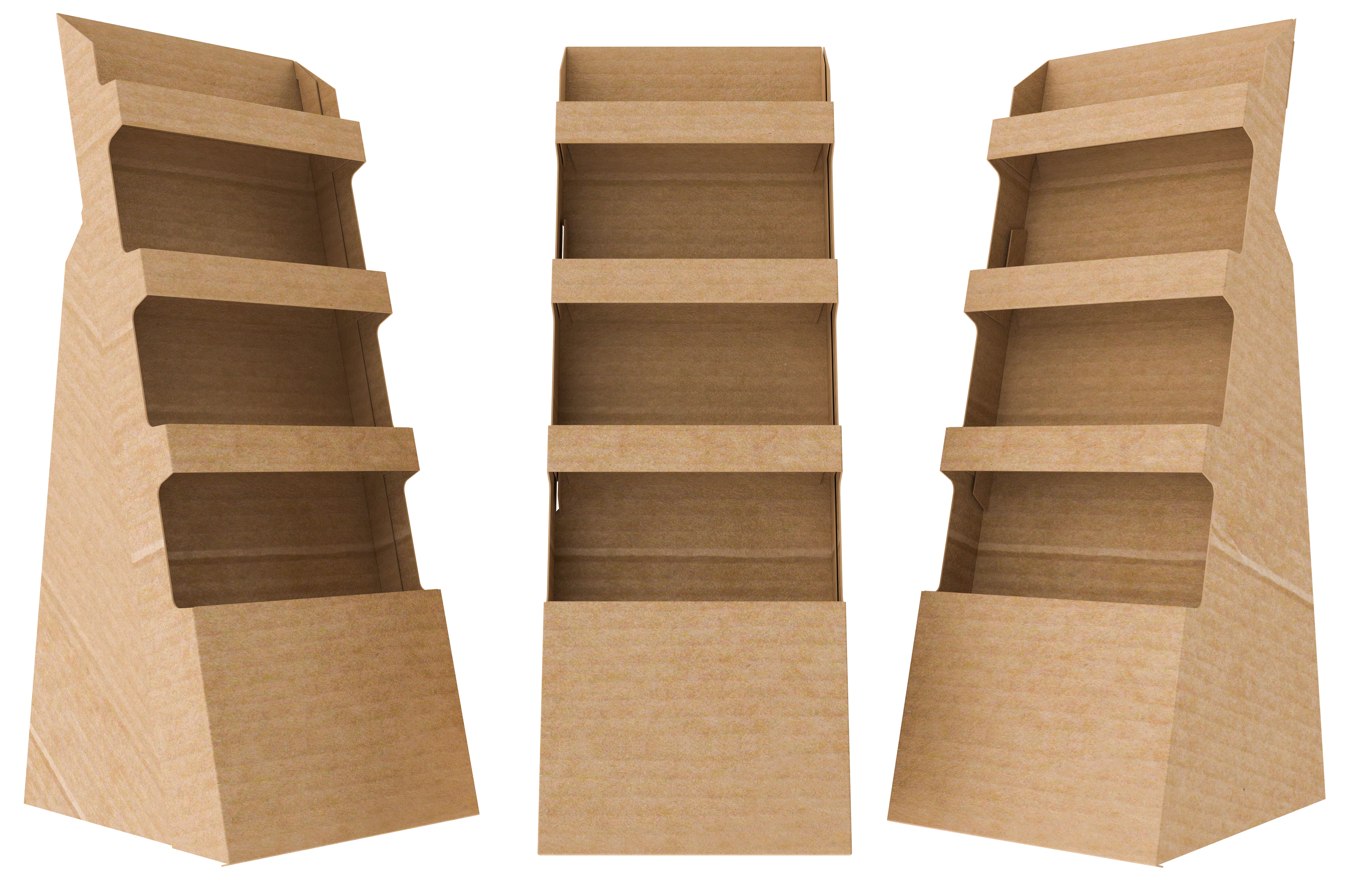

A well-known food manufacturer sought to redesign their existing POP display to enhance its visual impact on the retail floor and improve product visibility. At the same time, the client needed a solution that reduced material usage and supported their sustainability goals. Because the project had an accelerated timeline, the new design also had to be developed quickly without compromising structural performance or marketing requirements.

Adept Packaging was engaged to create a streamlined POP display that balanced aesthetics, durability, cost reduction, and speed-to-market.

The Challenge

The project required balancing structural engineering with marketing, sustainability, and timeline-driven needs:

The POP display needed to showcase the primary packs more prominently, increasing consumer visibility and on-floor differentiation.

The structure had to maintain an attractive presentation while still supporting inventory and movement through the supply chain.

The client wanted to significantly reduce corrugated material usage without sacrificing structural integrity.

The redesign needed to support broader sustainability initiatives across the organization.

Because the client required the display quickly, the solution needed to leverage existing structures where possible.

Minimal structural changes were preferred to speed approvals, production setup, and deployment.

Adept’s challenge was to design an improved display that met all structural, marketing, and sustainability benchmarks, without slowing down the project timeline.

Our Approach

To deliver a high-impact, sustainable, and rapidly developed display system, Adept followed a structured optimization approach:

Reviewed the billboarded primary pack tray design to understand opportunities for improved visibility and structural refinement.

Leveraged an existing display structure that already aligned with marketing requirements, enabling a significantly reduced development timeline.

Collaborated closely with the supplier to make minor structural adjustments while ensuring the display retained its durability and compression strength.

Presented multiple “show and tell” concepts to the client’s marketing team, who immediately approved the chosen structure for meeting all display and visibility expectations.

Validated compression and distribution performance, confirming the new structure could withstand transit and retail handling conditions.

Reduced total material use by 30%, eliminating 3,090 lbs of corrugated from the supply chain.

Generated $16,000 in material cost savings through strategic structural optimization.

The final design delivered strong visual appeal, reduced waste, and efficient production, exactly aligned with the client’s goals.

The Impact

The optimized POP display delivered significant improvements across sustainability, cost, performance, and speed-to-market:

30% reduction in material consumption (3,090 lbs saved)

$16,000 in cost savings resulting directly from reduced material use

Improved product visibility, enhancing retail presence and shelf impact

Accelerated development and deployment, thanks to a minimal-change approach

Simplified assembly with improved viewing angles and structural efficiency

Validated performance, meeting compression and distribution testing requirements

The redesign offered a faster, smarter, and more sustainable solution tailored to the client’s retail and operational needs.

This isn't just a fix. It’s a transformation.

Let’s Talk Efficiency Gains

Want to reduce production costs, increase throughput, or optimize your packaging line? Let’s connect.